Custom Designed & Specialty Balers

CUSTOM DESIGNED & SPECIALTY BALERS

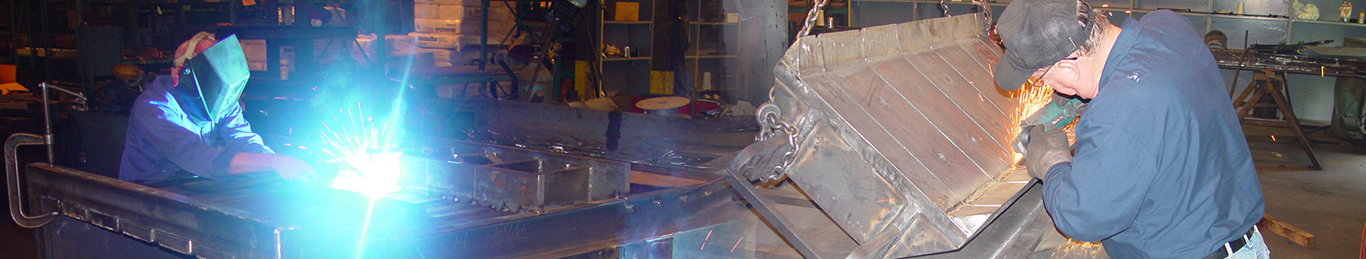

When needed, C&M engineers will custom design a baling press for your application, space requirements, or hard-to-bale materials. C&M Baling Systems can design baling press electrical controls to interface with customer selected programmable logic controllers (PLCs) and can assist with systems integration. C&M endeavors to take on baling projects other manufacturers won’t, and offer unique & creative solutions that work.

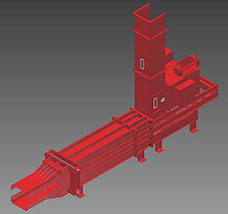

C&M's engineering department utilizes the latest version of Autodesk Inventor, which allows our designers to produce drawings for our custom and standard balers using 3D modeling. Our Autodesk software also allows the ability to produce 2D drawings for any version of AutoCAD.

Typical Custom Designed/Specialty Balers

Example 1

Custom designed C&M model 2424‐24‐OE27 open‐end manual tie baling press with a tall chute unloading into a 24" x 24" in‐feed opening. The custom designed baling chamber had fixed density controls and an attached bale bagging system with a springloaded roller conveyor. The material to be baled needed plastic straps, required a specific density & weight, and within an agreed final bale length. The completed bales had to be ejected directly into a combustible bag then easily palletized for transport.

Example 2

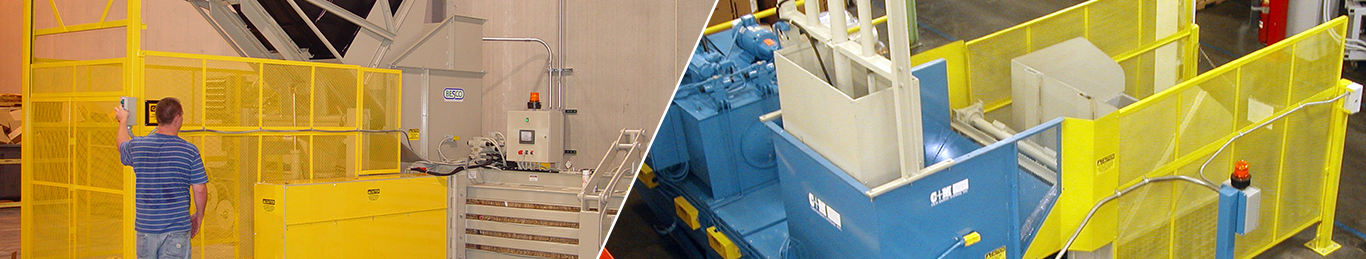

C&M model CM3030‐30‐AT37 open‐end automatic tie baling press fitted with a custom designed timed‐cycle in‐feed prepress to help increase infeed density, reduce the number of ram cycles, and produce well formed bales of a very light material. The light weight material was being fed from a cyclone.

Example 3

C&M model CM3030‐30‐AT37 open‐end automatic tie baling press fitted with a custom designed timed‐cycle in‐feed prepress to help increase infeed density, reduce the number of ram cycles, and produce well formed bales of a very light material. The light weight material was being fed from a cyclone.